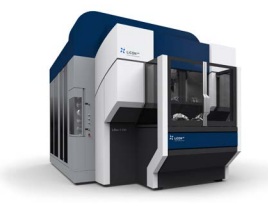

Licon machining centers are distinguished by an especially rigid machine design, which because of its compact modular design enables sustainable processing in new dimensions.

The twin-spindle LiFLEX II 444 MC insures that Licon’s focus is on 4-axis and 5-axis powerhouses that can machine complex work pieces on five sides for materials ranging from high-strength to light-metal alloys as well as being able to machine parts that are 445 mm per side and have a depth of 425 mm.

Variously configurable loading systems such as a gantry, robots, pallet changers and double-swivel trunnions facilitate an optimized load and unload process, shortening non-productive times and therefore reducing costs.

“Cost per part” is a high-priority criteria. Low component prices are not the only essential factor in making decisions; process safety planning and availability are all also brought into consideration.

A high-quality machining system, with reliable, precision metal removal to insure consistently volume quality, guarantees the maximum investment security.

The machining of sophisticated components in the automotive industry using traditional four-axis machines with three linear axes and a single rotary axis inevitably leads to a reduction in quality, be it through imprecision on account of multiple clampings or the use of angle heads.

Toolspecialist Licon utilizes 5-axis machining centers for compound angle machining in the majority of its projects.

In clamping multiple parts on a common 5th axis trunnion, the selection of the correct spindle-side linear-axes must be made. It is necessary to take into account the work piece tolerances, clamping technology and the e thermo-elastic strains present in this process.

There are some cases in which process capability can only be achieved by using individually configurable Z-axes or by using X, Y and Z-axes that are completely independent of each other.

Experience has shown that the ability to individually adjust the spindles represents significant added-value in the output of high-precision parts when the machining distances involved are large. Licon offers this with its LIFLEX twin-spindle platform with high-performance spindles in three distances: 450 mm, 700 mm and 1000 mm. |